MEKI AI + Windows 11 upgrade campaign

Upgrade your X-ray inspection systems to MEKI AI and receive a complimentary Windows 11 update. Ensure compliance and enhanced security before Windows 10 reaches end-of-life in October 2025.

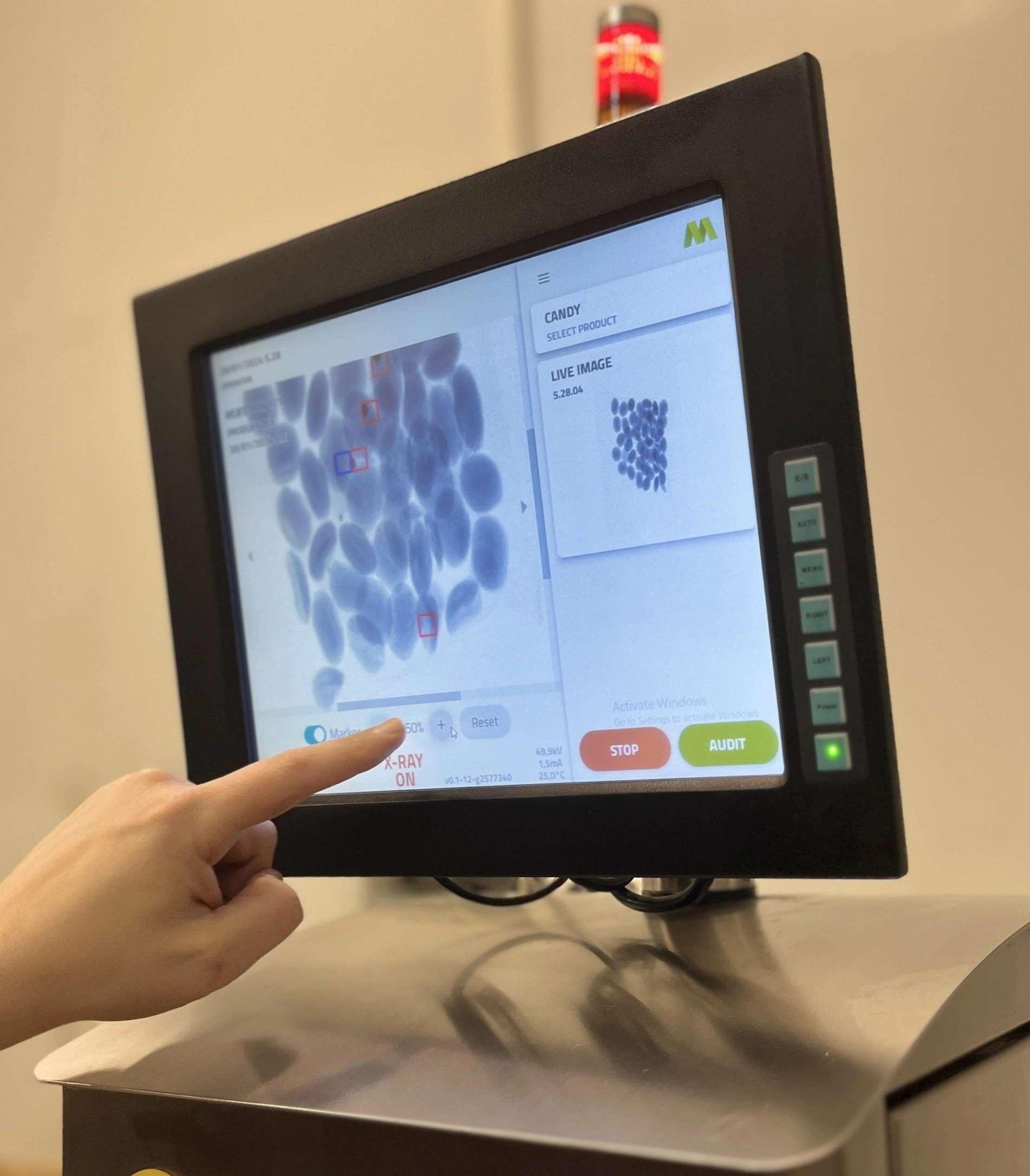

Trusted AI-powered X-ray inspection solutions enabling food producers to boost productivity and deliver only the best quality

Our X-ray inspection systems deliver value in two critical ways

Ensure food safety and quality by identifying and eliminating risks at critical control points in your production line

Identifies metals, glass, ceramics, hard plastics, and other foreign materials in your products

Rejects incomplete, broken, or misfilled products and those with compromised packaging

Ensures optimal performance of the Critical Control Point through automated system validations

Comprehensive food safety and production intelligence systems for your entire operation

Advanced detection technology for nearly all primary packaged food products.

Specialized accessories designed for regulatory compliance and reporting.

Comprehensive service packages for maximum uptime and optimal performance.

Tailored solutions for quality assurance and regulatory compliance.

Hear from food manufacturers who trust our X-ray inspection systems to ensure quality and safety

''We got plenty of offers, but Mekitec's systems turned out to be the best value for our investment.

''

''Mekitec's X-ray system is great – it's compact, small, and easy to handle for all operators.

''

''I would recommend the Mekitec X-ray equipment because of the cost-effectiveness, reliability, and high level of technical support.

''

''In order for us to comply with demanding standards, we use Mekitec X-ray systems.

''

Ready to enhance your inspection process? Let's discuss how our solutions can meet your specific needs.