Prevent food spoilage

Detect leaking seals with Mekitec’s X-ray systems

Leaking seals are costing you more than you may think

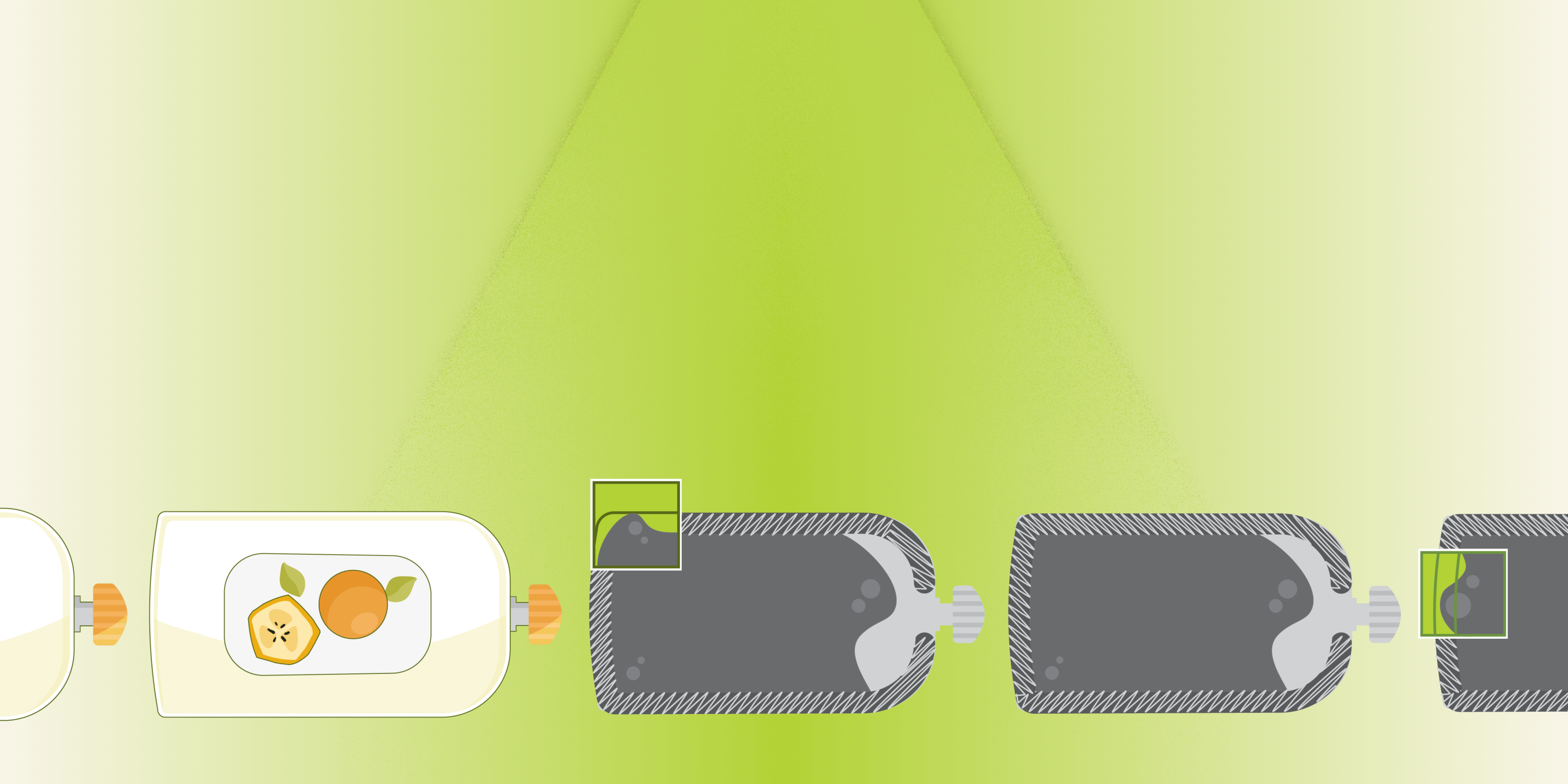

Every year, billions of dollars are lost in food spoilage caused by compromised package seals. Whether it’s contamination, reduced shelf life, or wasted materials, leaking seals affect your bottom line and your brand’s reputation. Mekitec’s seal inspection ensures that your products are ready to meet consumer expectations. By analyzing the product and package’s seal areas in real-time, the seal inspection identifies leaking packages before they become costly problems.

Seal Inspection Designed For Food Producers and Co-Packers

Mekitec’s seal inspection technology ensures your products meet strict safety and quality standards by detecting contaminants and food residue trapped inside the seal area. Industries with high-value food products benefit the most, as early detection of seal defects and leaks prevents recalls, spoilage, and financial losses. Key segments include:

- Meat & Seafood – Compromised seals in vacuum-packed meats and seafood can lead to spoilage and bacterial contamination. Seal inspection prevents these risks, ensuring products remain fresh and safe.

- Dairy Products – Yogurt, cheese, and other dairy items require precise seal integrity to prevent bacterial growth and maintain freshness. Mekitec’s seal technology detects even the smallest traces of food residue in the seal area, reducing waste and extending shelf life.

- Ready-to-Eat Meals – Fresh salads, ready meals, and other convenience foods rely on perfect seals to preserve taste, texture, and shelf life. Mekitec ensures leak-free packaging, protecting both consumer trust and product quality.

- High-Value Specialty Products – For premium, organic, and niche food segments, maintaining seal integrity is essential to safeguarding brand reputation and meeting consumer expectations.

Why X-ray Outperforms Other Inspection Methods

- Sees Through Opaque Packaging – Unlike vision cameras and sensors, X-ray penetrates films, foils, and multi-layer materials, ensuring no seal defect goes undetected.

- Reliable Detection Where It Matters Most – While X-ray may have limitations in detecting small holes or openings in the seal area, completely open seals in many product types often leave behind product residue, making them detectable. More importantly, X-ray excels at identifying trapped product, contamination, and structural seal defects – the primary causes of food spoilage, waste, and recalls.

- All-in-One Inspection – Combines seal integrity, foreign object detection, and quality assurance in a single, compact system – eliminating the need for multiple inspection stages.

- Actionable Insights for Improvement – Real-time data helps identify recurring seal issues, allowing you to optimize packaging processes and enhance quality control.

Take the Next Step in Product Quality & Safety

With Mekitec’s Seal Inspection, you gain unparalleled visibility, enhanced food safety, and operational efficiency – all within a single X-ray system. Don’t let undetected seal leaks lead to waste, recalls, and brand damage. Upgrade your packaging inspection today and ensure that every product leaving your facility meets the highest quality standards.