Detecting

Stone Contaminants

from Food Products

Stone Detection in Food Production

Stone contaminants are more common in industries where the raw material comes from fields, e.g. nuts, vegetables, and fruits. When ingredients are harvested from the field, there is a risk that some rocks or stones get picked up as well.

This is why it’s important that even the raw material suppliers have proper safety processes in place, helping to minimize the contamination risk at the early phase of the supply and production processes.

Global as well as local food safety standards, such as Food Safety Modernization Act (FSMA), drive towards this kind of approach, where you prevent the possible contaminations and eliminate the risks before the finished food product reaches the consumers.

However, the final food products should also be inspected in case some of the contaminants slipped through the initial inspection that took place in the suppliers’ facilities, or if there is a contamination risk at the final production and packaging facilities.

And when it comes to rock or stone contaminants, it is possible that they are left unnoticed if the products go from field to shelves without going through an X-ray system. This is where metal detectors are a lacking inspection solution since they are not capable of detecting other foreign materials.

The Difficulties You Might Face with Detecting Stones in Food

X-ray inspection systems are mostly capable of detecting stone contaminants, but there are still some challenges when it comes to different types of stones and rocks. The density of different stone types can vary from 2.3g/cm3 to over 3.0g/cm3 (the density of water and typical food products is 1.0g/cm3, and in general densities above that are detectable with X-ray – see the graph for reference). This is why it’s important to tie the Critical Control Point’s detection limits to a known and certified contaminant (e.g. ceramic) that also represents the density of the possible rock or stone contaminants.

Even stones of the same type can vary in the density since they can contain different amounts of minerals, which make them either less dense or denser (e.g. granite, which can have a quartz content anywhere between 20 – 60%). This is the usual case with contaminants which come from nature – we cannot be completely sure about the properties of these materials without some further testing.

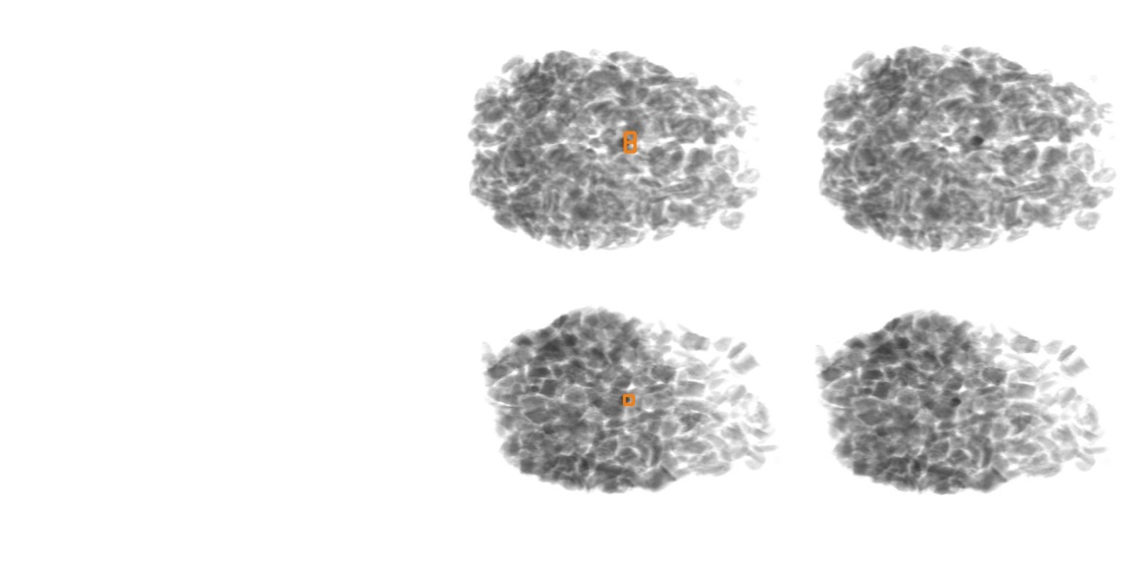

It’s important to keep in mind, that the detection performance for stones (and other contaminants) also depends on the properties of the inspected product (e.g. content, texture, density). If the product is very heterogeneous (meaning a lot of density variations within the product or package), the detection is more difficult than with homogeneous products.

Detect Stone Contaminants in Your Food Production with X-Ray

In order to be able to detect stones in the food products, it is important to test the detection performance with your products and actual stone contaminants. During the tests, we can use e.g. ceramic as a comparison to the stone contaminants. Based on the results we can give a better estimate on the detectability of certain type of stones with the said density.

We offer free-of-charge testing for your food products, where the exact detection rate is determined for the certified foreign objects (e.g. SUS, glass, and ceramic), but we can also test the products with your actual foreign bodies, such as stones, that you might have found in your production.

we want to help you

More information

We at Mekitec can help you to identify the best inspection solution for your products by conducting a thorough Application Test where we determine the exact detection performance for your products. Contact us to book your test!

You can also download our free white paper and learn eight things you should know about Application Tests and how food producers can benefit from it:

Download free white paper here