MEKI AI + Windows 11 upgrade campaign

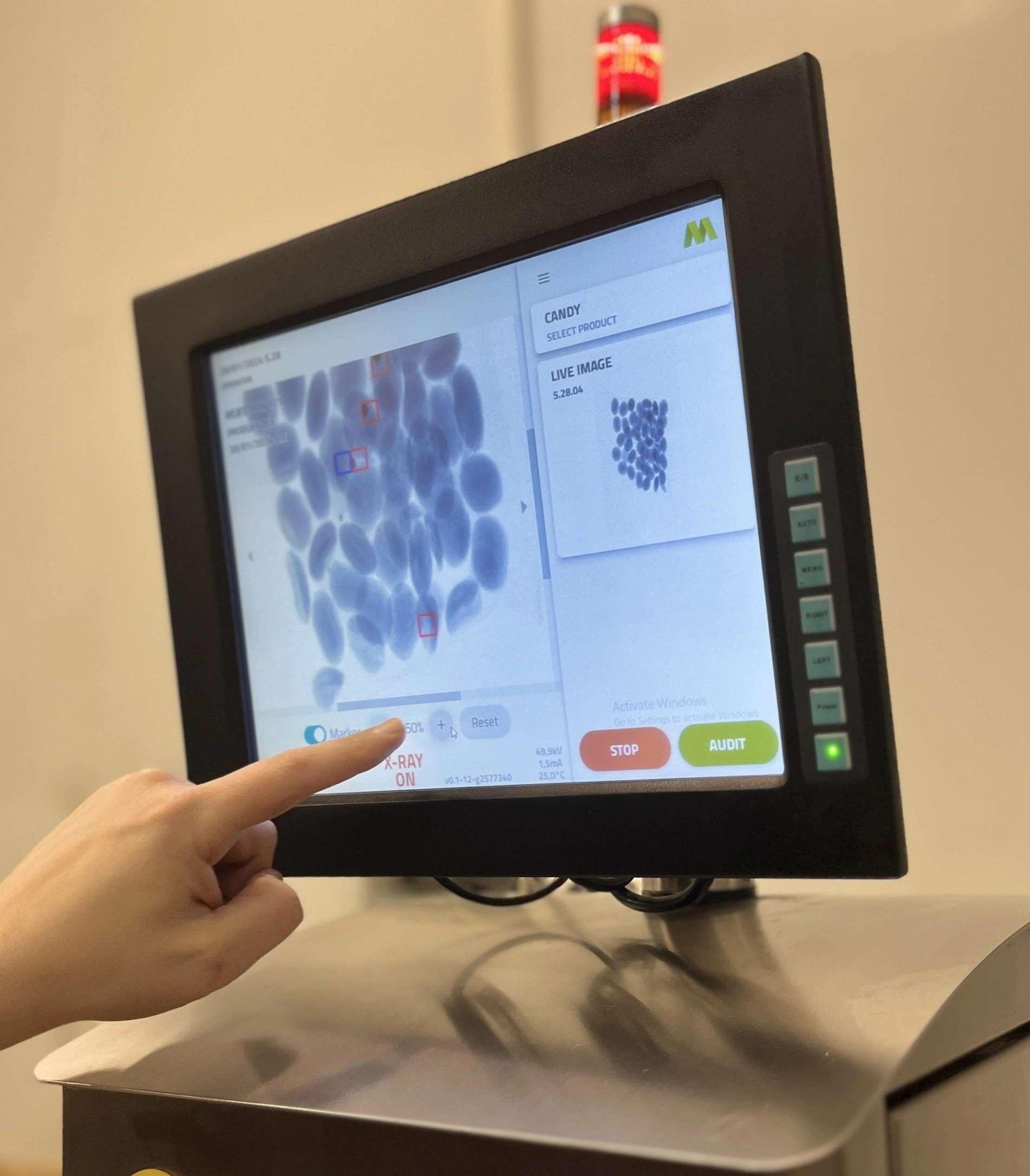

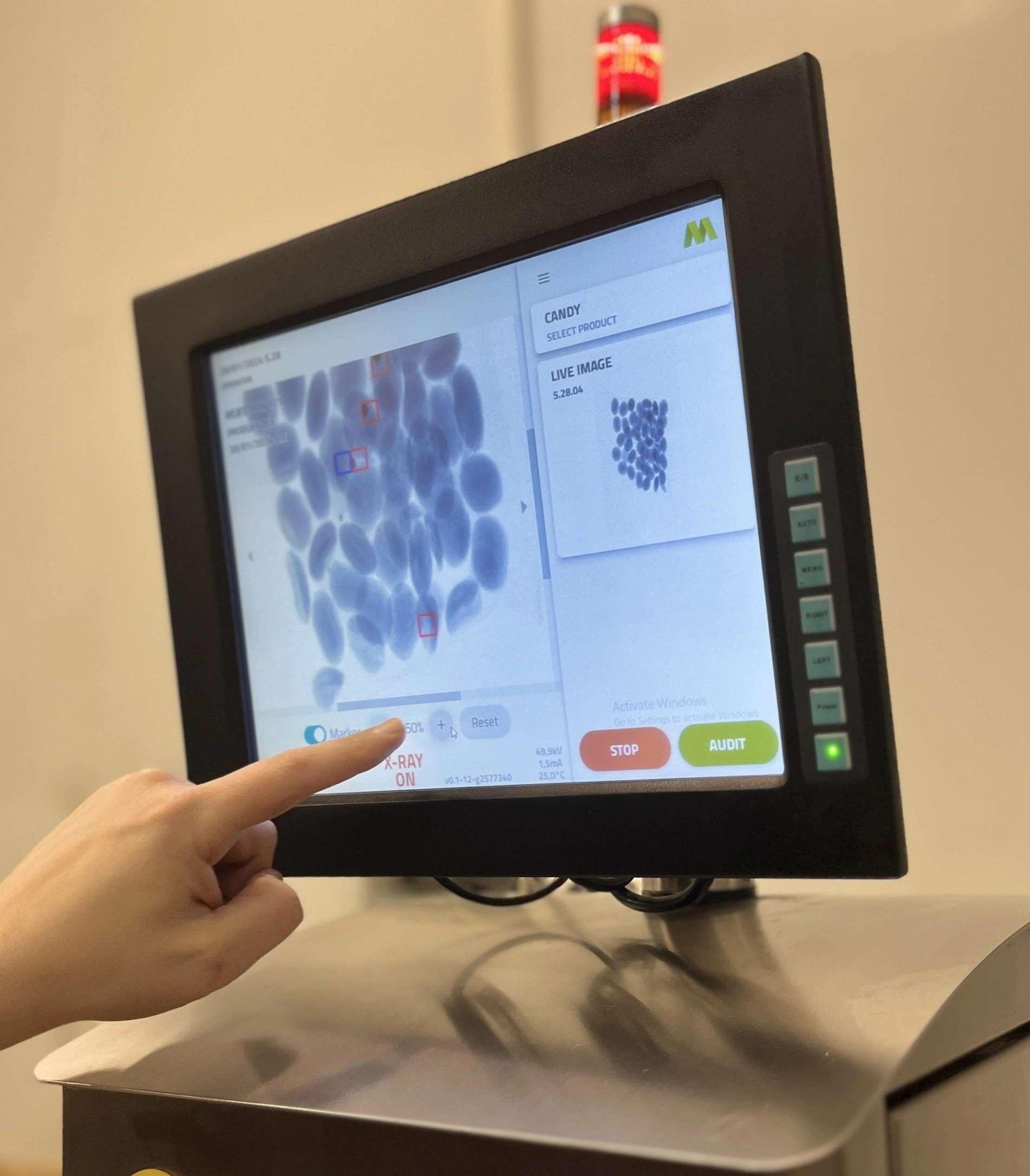

Upgrade your X-ray inspection systems to MEKI AI and receive a complimentary Windows 11 update. Ensure compliance and enhanced security before Windows 10 reaches end-of-life in October 2025.

Expert perspectives on food safety, X-Ray inspection, and production intelligence

Upgrade your X-ray inspection systems to MEKI AI and receive a complimentary Windows 11 update. Ensure compliance and enhanced security before Windows 10 reaches end-of-life in October 2025.

Discover how advanced X-ray inspection helps food manufacturers meet U.S. safety regulations, prevent contamination, and ensure compliance with FSMA and HACCP standards.

Learn how Costco's new mandatory X-ray inspection requirements are revolutionizing food safety standards, and discover what suppliers must do to stay compliant and competitive.

Discover how Mekitec's Quality Studio transforms food production with data-driven X-ray inspection insights. Optimize quality control, improve traceability, and make informed manufacturing decisions.

Learn how NASA-developed HACCP principles can help food manufacturers systematically manage risks, prevent contamination, and ensure consumer safety through comprehensive quality control strategies.

Explore comprehensive X-ray inspection techniques for food manufacturers, including advanced quality control, process optimization, and strategic data management to enhance food safety and production efficiency.

Discover how MEKI™ Data Manager transforms food production quality assurance through automated X-ray data management, HACCP compliance tracking, and actionable insights for safer, more efficient manufacturing.

Complete guide to understanding radiation safety in food X-ray inspection, covering radiation levels, health risks, and best practices for ensuring food quality and operator safety in modern food production facilities.

Discover the safety of X-ray inspection systems in food production. Learn about radiation levels, operator protection, and how X-ray technology ensures food quality without risks.