SIDEMEKI™

Superior X-ray inspection for tall packaging applications

SIDEMEKI™ delivers the best value X-ray quality control for tall packages, both liquids and solid foods alike. This inspection system brings a new approach changing the existing standards towards true pack-for-pack traceability. Now, the benefits of primary packaging X-ray inspection is available for side-view applications, such as PET bottles and containers.

SIDEMEKI™ – X-Ray Quality Control for Tall Products

The SIDEMEKI™ system is designed for production lines where the food is in packages that are taller than wider, such as bottles, cartons, containers and cans. Ensuring smooth production flow is essential with these packaging types, setting a higher expectation for the design of the inspection equipment.

SIDEMEKI™ is the only quality control solution offering food producers a choice to select one or two X-ray generators based on the exact need for the product inspection. With tall products, this means that the system always has the needed inspection accuracy necessary for foreign object detection and specific quality functions, e.g. fill level and cap inspection. This equals the best value in the industry

Technical Specifications

| Conveyor speed | 0.1 - 0.7m/s(1) |

| Conveyor motors | 2 x motor roller 230VAC, IP69K |

| Conveyor load capacity | Max. 70kg(2) |

| X-ray generators | 1 or 2 X-ray generators, 200W |

| X-ray leakage | less than 1 µSv/h |

| Detector | 1 or 2 detectors, linear scanner, resolution 0.4 mm |

| Software | Mekitec X-ray inspection System SW |

| Operating system | Windows 10 |

| Connectivity | 2 x USB, 1 x Ethernet |

| HMI | 15” Color TFT LCD Screen |

| Operation | Temperature 0–35° C ambient |

| Cooling | Optional 1000W air conditioner |

| Noise level | < 81.3dB(A) |

| IP rating | IP65(3) |

| Relative humidity | 30-85%, non-condensing |

| System power supply | 110/240 VAC, 50-60Hz |

| Dimensions | Width: 3450mm Depth: 1325mm or 1625mm depending on the rejection bin(4) Height: 2360mm |

| Weight | 830kg, with cooling unit 880kg |

| Material | Stainless steel, brushed |

| Reject options | 1 rejecter: for foreign object detection and other quality functions like fill level and cap detection 2 rejecters: 1st for foreign object detection, 2nd for other quality functions Set-up will be selected based on the application |

| Rejection confirmation | Available as an option |

| Rejection box | Option 1: 700mm depth, 330mm width Option 2: 400mm depth, 330mm width |

| System conveyor | EU and FDA food use approved conveyor chain belt |

| Radiation protection | Meets EN 61010-02-091, FDA CFR 21 part 1020, 40 |

| Safety system | Safety Circuit CAT 3, Performance Level PL d |

| In-feed/out-feed options | Option 1: end-feed Option 2: side-feed |

(2) Load must be evenly distributed on the conveyors.

(3) Air intakes (IP54) and optional cooling unit (IP32) require the use of protective cleaning covers.

(4) When equipped with cooling unit, the depth is 1600mm or 1900mm

Detection Area

Maximum detection area based on product height (mm)

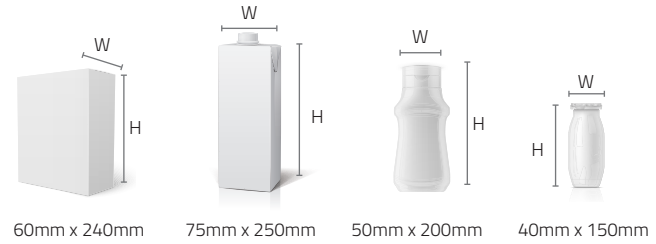

Product Examples (W x H)

Mekitec Oy, info@mekitec.com, www.mekitec.com

Disclaimer: All information is provided for information purposes only and shall not be considered as assured characteristics. The information and technical data presented in this document are subject to change. Customers should obtain and verify the latest relevant information before placing orders. If you have any questions related to the datasheet, please contact us via email or phone. Thank you.

Copyright 2023 Mekitec Ltd. All rights reserved

Key Features

Two X-ray Configuration

Optional one or two X-ray generators tailored to your specific inspection requirements

Tall Package Optimization

Specialized design for bottles, cartons, containers and cans where height exceeds width

Pack-by-Pack Traceability

Complete traceability system ensuring quality control for each individual package

Production Flow Integration

Engineered for seamless integration without disrupting production line efficiency